Make it Safely: What to Wear in Your Workshop | Make:

Jul 01, 2015· Make it Safely: What to Wear in Your Workshop Jeremy S Cook Jeremy is an engineer with 10 years experience at his fulltime profession, and has a BSME from Clemson University.

WhatsApp)

WhatsApp)

Jul 01, 2015· Make it Safely: What to Wear in Your Workshop Jeremy S Cook Jeremy is an engineer with 10 years experience at his fulltime profession, and has a BSME from Clemson University.

Feb 11, 2019· Mechanical Engineering Workshop Full Job create by Using Grinding Machine. Tool create by Engineering''s. Major and minor Project Workshop in Engineering Department. Grinding, CNC Machine using in ...

Practical Approaches to Engineering Noise Controls Dave Yantek Mining Hearing Loss Prevention Workshop June 2122, 2005 ... Mechanical Noise ... Drilling, cutting, grinding Electric motors Bearings Gears Conveyor systems Sources of Flow Noise Ventilation systems Engine cooling systems Water sprays Dust scrubbers

Mechanical workshops safety rules are devised to make things easy, for the workers and workshop managers simultaneously. Workshops include working with heavy machinery, power tools, chemical substances, and other materials that may have health risks. However, sticking to these guidelines will ensure that employees working in the workshop are safe and proper emergency measures are .

Cutting and grinding is performed on many jobsites. The following are a list of safety precautions that must be followed to prevent injury or property damage. Stay alert and watch what you are doing. Do not use tool while tired or under the influence of drugs, alcohol or medication.

Workshop Technology Practice . ... transmitted, in any for m or by any means, electronics, mechanical, photocopying, ... making it ideal for the home workshop and small factory alike.

offers 736 mechanical sanding products. About 22% of these are machining, 3% are abrasive tools. A wide variety of mechanical sanding options are available to you, such as sanding paper, abrasive disc, and abrasive block.

This Series of grinding and polishing machines offer practical and economical solutions to your metallographic sample preparation needs. Included is a microprocessor controlled sample mover designed to be used with grinder / polishers. It is ideal for medium size .

Standard Operating Procedure – Standard Polisher/Grinder About this SOP This document describes the standard operating pr ocedure for using the polisher/grinders in room 157 Engineering II. It covers hazards, emergency procedures, basic specifications and operating procedures. Who to Contact

TYPES OF GRINDING MACHINES From the simplest grinding machine to the most complex, grinding machines can be classified as utility grinding machines, cylindrical grinding machines. and surface grinding machines. The average machinist will be concerned mostly with floormounted and benchmounted utility grinding machines, bufting machines. and ...

Jan 30, 2019· Fitting Definition: Fitting is the process of assembling various parts manufactured in the machine shop. The various types of tools used in Engineering Workshop are as follows. In the last class, we had discussed about Electrical Engineering Workshop in a detailed way and Today we are going to discuss about Engineering Fitting Workshop.. Note: Watch YouTube Video at the middle of the Article.

Handheld angle grinders have long been used extensively in the metal fabrication and welding industries; however, they also now are being used more frequently in the mechanical contracting, autobody, masonry, and stoneworking industries for grinding, cutting, and polishing.

Young woman gridning metal in mechanical workshop, senior man supervising woman and teaching, employee training

Grinding, Honing Polishing (Workshop Practice) [Stan Bray] on *FREE* shipping on qualifying offers. For those interested in model engineering and mechanical crafts, this book presents a general overview of the grinding

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.. A wide variety of machines are used for grinding: Handcranked knifesharpening stones (grindstones)Handheld power tools such as angle grinders and die grinders; Various kinds of expensive industrial machine tools called grinding machines; Bench grinders

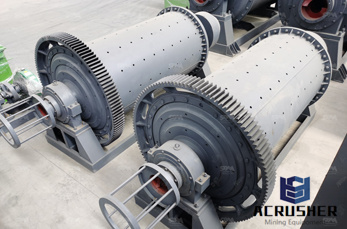

A grinding machine, often shortened to grinder, is one of power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting grain of abrasive on the wheel''s surface cuts a small chip from the workpiece via shear deformation.. Grinding is used to finish workpieces that must show high surface quality (, low surface roughness) and high ...

MECHANICAL WORKSHOP Presentation on By: Hafiz Muhammad Rizwan . PPE Suitable Personal Protective Equipment must be used before using a tool, Machines, check its safety instruction . PPE Head protection Eye and Face protection Hearing protection Arm and Hand protection

3. Milling • Milling – A machine operation in which a work part is fed past a rotating cylindrical tool with multiple edges. (milling machine)

Workshop safety. The safety in Workshops has been written not only to provide appropriate safety procedures but also to assist trained workshop personnel with the provision of a reference document outlining the general principles of safe working practices relevant to the mechanical engineering aspects.

Our mechanical workshop is equipped with an Okuma LT15 CNC lathe. This 5 – axis machine tool is complete with twin chucks and turrets. Each turret consists of 12 stations which can carry live tooling with speeds of between rpm.

Grinding machines for metals with sturdy sheet metal frame. The design of models 75 and 150 provides userfriendly costeffective operation that are the basic feature of the entire range. Powerful motors for high performance. P rice Grid 75 € 669,90 . Price Grid 150 € 888,30

M. S. Enterprises is a prominent and trustworthy name in Trading of Machine Tools with over 30 years of experience. The company is establish in the year 1983 by Mr. Mendra. M. Sh and is now headed by his son Mr. Rushabh. M. Sh. The company deals in all types of workshop machineries, both heavy duty and light duty such as:

Apr 25, 2019· Generic Mechanical Workshop risk assessment. An assessment of the potential health and safety hazards in a mechanical workshop. ...

Mechanical Workshop Safety. Milling Machine and Lathe Dont leave spanners or keys on rotary parts. Never apply a wrench to revolving work. Always clamp work pieces and holding devices safely and firmly. med Amer ( HSE Mechanical Workshop Safety. Milling Machine and Lathe Do not use your hands to remove cuttings while a machine is in motion.

WhatsApp)

WhatsApp)