maintenance to ball mill

method for maintenance of ball mill CGM . ball mill maintenance and repairStone Crusher,Rock The ball mill common cause of the malfunction and its elimination method are shown in the following table ... Chat Online

WhatsApp)

WhatsApp)

method for maintenance of ball mill CGM . ball mill maintenance and repairStone Crusher,Rock The ball mill common cause of the malfunction and its elimination method are shown in the following table ... Chat Online

method for maintenance of ball mill for sale. Ball Mill Maintenance amp; Installation Procedure. Another good method of preventing this pulp race is the use of the sponge stone which can be cemented in place General Ball Mill Maintenance After the mill is erected, in order to avoid overlooking both obvious and obscure installation details, we ...

The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media. The material grinding occurs during impact falling grinding balls and abrasion the particles between the balls.

the ball mill maintanance The ball mill maintanance – Grinding Mill China Methods to maintenance and repair the ball mill – Essay – wang The ball mill is a key equipment for grinding materials widely used in powdermaking production line such as cement silicate sand newtype building material Contact Supplier Get details

method for maintenance of ball mill. ball mill maintenance and repair method xinhai. ball mill is the largest consumption equipment of mining ball mills operating state directly influences the whole mill plant productivity. its also the biggest investment equipment of mill plant, and the wastage of the ball mill has a direct relationship with mill plant operating costs.

The irregular granularity of the ball mill, an abnormal phenomenon when the fineness of the qualified materials getting thicker and the granularity is beyond control

May 08, 2015· Great Wall ball grinding mill process ball grinding mill working principle 3D our website:, our email:salesgw...

Principle of overflow ball mill: the main component is a cylinder with diameter and length at a reasonable by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in .

mining method for maintenance of ball mill Mine mill (ball grinding mill) is an important equipment used for recrushing, .. of machine, operating regulations, maintenance methods and steps, safety, etc. Get Price MTM Continental trapezoid milling machine, rock phosphate

Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and .

Its also the biggest investment equipment of mill plant, and the wastage of the ball mill has a direct relationship with mill plant operating costs. Therefore, it is very important to maintain and overhaul the ball mill regularly, reasonable and effective maintenance can promote the ball mills .

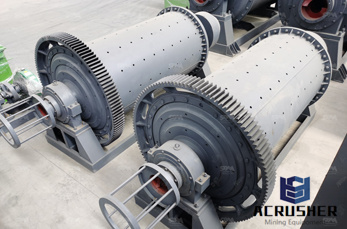

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

These mills are characterized by their large diameter and short length, as compared to ball mills. The inside of the mill is lined with lifting plates to lift the material inside the mill, where it then falls off the plates onto the rest of the ore monitoring of this type of equipment is crucial for modern mining operations.

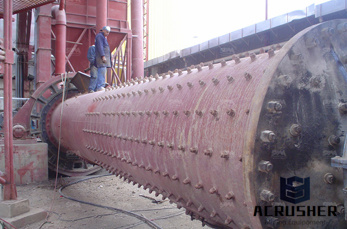

This maintenance method is to repair the large girth gear without replacing the barrel of the large girth gear of the ball mill and the spring plate. It is necessary to cut the spring plate and the ear plate of the large girth gear first, and the cylinder and the previous spring plate can be kept still.

Aug 20, 2014· With this in mind, the ball mill is an essential item of machinery, and its proper maintenance is an equally essential concern. You''ll already know that a ball mill gets its name from the manner in which it breaks down hard materials, like ores.

Procedure maintenance ball mill. Procedure maintenance ball mill greenrevolutionorgin maintenance procedures of ball mill maintenance procedures of ball mill the xsm is the professional quarry crusher machine manufacturer in the world, loed in china,india, along with other asian mar.

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

Methods to Maintenance and Repair the Ball Mill. The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Ball mill.

Grinding ball mill is also the biggest investment equipment of mill plant, and the wastage of the ball mill has a direct relationship with mill plant operating costs. ... Ball Mill Maintenance and ...

MAINTENANCE OF BALL MILLS. Maintenance of Ball Mill. ... Ball mill operation and maintenance,ball mill operating methods. To make the ball mill operate good, we must strictly abide by the operation and maintenance procedures. Patterson Industries – Ball Pebble Mills

Method for manual ultrasonic testing and result analysis of steel welds shall conform to GB. Ball Mill ... Ball mill maintenance checklist ... effects of grinding media shapes on ball mill performance Ball size distribution inside an industrial mill was analysed in terms of ...

Ball mill is the largest consumption equipment of mining plant. The ball mill''s operating state directly influences the whole mill plant productivity. It''s also the biggest investment equipment of mill plant, and the wastage of the ball mill has a...

Apr 09, 2012· The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Ball mill can grind various ores and materials with dry type or wet type.

Objectives. The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the maintenance inspection of the ball mill system.

WhatsApp)

WhatsApp)