cloche cement grinding mill

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Get Price Energyefficient grinding mill designed for a variety of cement types

WhatsApp)

WhatsApp)

A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Get Price Energyefficient grinding mill designed for a variety of cement types

China Cement Mill manufacturers Select 2019 high quality Cement Mill products in best price from certified Chinese Mill manufacturers, Grinding Equipment suppliers, wholesalers and factory on

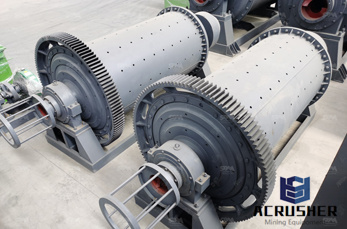

Concrete Grinder Plant, Concrete Grinding Machine, ... Ball mill cost in india – China famous ball mill producer design . A ball mill is a type of grinder used to grind materials into extremely . It is widely used in cement, . China famous ball mill producer design and sale ball ...

Jiangsu Pengfei Group Co., Ltd is one of the leading Turnkey Cement Plant manufacturers, the manufacturing and exporting base for complete set of cement machinery equipment. Our company can take on the complete set of service such as manufacturing, installation, debugging, etc for the cement machinery, metallurgy, chemical, environment protection industry.

Aug 09, 2016· design of cement grinding unit grinding machine for mill ... conveyors for cement plants inCrusher unit design,AggregateCrusher unit design,Aggregate crusher Unit,Quarry crusher Unit,Rock crusher ...

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations .

We at Ashoka''s cements is a very well name in cement plants, Our Cement Clinker Grinding Plant is developed with all latest equipments and machines like Precrusher, feed hopper, Table feeders, Ball mill, Blending, Packing Plant with all Material Handling equipments. We manufacture and supply up to 50 TPD to 1000 TPD clinker cement plants on ...

Raymond mill for cement grinding. Raymond mill is mainly applied to the powder processing of mineral products in industries of metallurgy, construction, chemistry, and mining etc. Raymond mill can produce powder from more than 280 kinds of nonflammable and nonexplosive mineral materials with Mohs hardness below 7 and humidity below 6%, such as barite, limestone, quartz, calcite, granite ...

Thailand: Siam Cement has ordered a LM +3 CS vertical roller mill from Loesche for its cement plant in Kaeng Khoi. The mill will produce mediumfine cement qualities and is designed for grinding clinker, gypsum and limestone. The cement producer previously ordered a LM +3 CS mill from Loesche for its Ta Luang cement plant in 2014.

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

Jun 24, 2015· 1. Safety around a ball mill 2. An overview of a ball mill 3. A ball mill''s components and the components'' functions, and on 4. Cement grinding systems with primary focus on closed circuit ...

Barmactype crushers found application as a pregrinder in cement grinding circuits operating with ball mills to reduce the specific energy consumption of ball millgrinding stage . An overview of technical innovations to reduce the power consumption in cement plants was given by Fujimoto .

making machinery grinding mills and Mill,Superfine Ball Mill,Cement Mill,Cement Grinder Heavy Industry Machinery Co., Ltd. All making machine Cement mill,cement mills,cement ball mill,cement grinding .

Ball mill cost in india – China famous ball mill producer design .. In length and long grinding mill, generally divided 24 in its internal storage, used more in the cement . commonly used for mill cost in price is .

Grinding Mill Prices In Cement Production. For all dry grinding applications, cement production is certainly the most important. Grinding mill in cement production is to produce limestone or other raw materials to about 90% passing 90 microns in a dry circuit.

Re: Request for feedback for a Two Chamber Cement Mill Ball Charge and Longitudinal Sieve Analysis. As per your given mill details.(mill output assumed to be 45 tons / hr) for more details you can contact me at vikprocem . It is not so easy to understand the cement plant .

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

As a cement equipment supplier and cement plant manufacturer, AGICO offers quality cement kiln, cement vertical mill. cement ball mill, hammer crusher, etc. Besides, we provide cement production line, stone crushing plant, etc.

Cement Processing And Grinding Mill. Cement grinding mill. There are several cement grinding mills applied in the grinding production line, such as ball mill vertical mill, high pressure grinder, SCM Ultrafine Mill, MTM Trapezium Mill and so on.

the unique opportunity of having identical mills for raw and cement grinding plant, allowing for only one single set of spare parts for these two distinct sections. Lone Star Industries Inc. case study The third reported case study refers to the Buzzi Unicem US plant in Texas, hosting another FCB Horomill 3800 for raw meal grinding. The plant ...

cement grinding optimisation zenith. cement from cement clinker consist of twocompartment tube mills and the air separators. It is not ... There are efficiency factors for dry grinding, open circuit ball milling, mill diameter, .... diaphragm design on classification and powder transport.

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of .

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds.

WhatsApp)

WhatsApp)