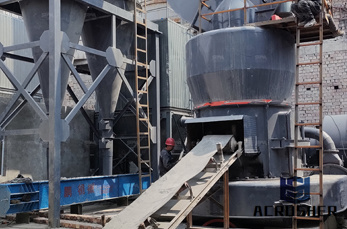

High pressure suspension grinding mill Manufacturer ...

clirik supply High pressure suspension grinding mill, are you looking for micro powder grinding mill and ultrafine vertical mill? Shanghai Clirik Machinery Co., Ltd is here.

WhatsApp)

WhatsApp)

clirik supply High pressure suspension grinding mill, are you looking for micro powder grinding mill and ultrafine vertical mill? Shanghai Clirik Machinery Co., Ltd is here.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

vertical grinding mill price in malaysia Consultax. Initially, this focused ongrindingcoal and the cement raw materials, with the adoption ofverticalrollermillsfor cement productgrinding– with its finergrindingrequirements coming more recently, in the late 1990s. + What Is ThePriceOf TheVertical Grinding Mill Of Talcum. vertical grinding mill price in malaysia The Pennefather.

Grinding Media In Cement Mill akaeltede. Line Diagram Of Cement Mill Grinding Media Cement mill Wikipedia OverviewHistoryMaterials groundTemperature controlBall MillsRoller millsHighpressure roll pressesCapacity of cement mills A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement .

It is available for raw grinding and processing all kinds of cement from Portland to blast furnace slag cements and pozzolanic. There are several diameters of grinding ball available, 50 100 mm to ensure grinding efficiency and it can be tailored to the needs of your grinding mill.

Vertical mill; Grinding media. Magotteaux is the only supplier offering the full range of grinding balls in particular and grinding media in general: cast and forged, low and high chromium, balls/boulpebs/rods and ceramic grinding beads and balls. ... As the kiln is considered the heart of the cement plant, any failure of heat resisting ...

OK mill, 274, 304 models are 253, 334, 364 5, 253 3 roller mill, the remainder is 4 and. OK vertical mill grinding clinker production was 55 ~ 165t/h, the slag yield is 35 ~ 100 t/h, grinding with OKS high efficiency separator, a grinding roller turning device. The vertical mill cement grinding power consumption is low, grinding cement ...

CEMENT ADDITIVES FOR VERTICAL MILLS 06 The different manufacturers of vertical mills mainly distinguish themselves in the shape of the grinding rollers and therefore the grinding plate''s profile. The dynamic separators are the same as the ones used on tubular ball mills, obviously adapted to the vertical grinding machinery.

Thanks to a bed material grinding concept, the vertical FCB Emill offers power consumption reduced by 50% compared to the ball mill for coal grinding. Customer benefits .

Types of cement mill liners: classifyingliners Classifyingliners are the best form of cement mill liners to adapt the grinding charge to the feed material´s granulometry while keeping a smooth material flow going. They are efficient energy wise because of the constant optimum grinding .

The OK™ Mill was originally designed for cement grinding. In 2017 we released the OK™ vertical roller mill for raw materials grinding. The OK™ Mill''s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size and application.

Vertical Cement Grinding Mill produced by China ZK Corp is is a new type of high efficiency, energy conservation and environmental protection of grinding equipment, widely used in the grinding of raw cement, slag, cement clinker, raw coal and other raw gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high .

The cement vertical roller mill is one of the most important cement equipment it is the key grinding machine of materials being crushed the cement grinding mill plays a vital role in cement production line and cement production process. Loesche Vertical Mill Lm Youtube. Nov 16 2011 process in vertical raw mill this feature is not available ...

vertical cement grinding mill cyprus Vertical Cement Grinding Mill is mainly used for grinding raw meal, clinker, Ground Granulated Blast Furnace Slag, iron ore, limestone, coal powder, coke powder, coal ...

VSI6X Sand Maker. Due to the increasing market demand for the scale, intensification, energy conservation, environment protection and highquality machinemade sand, ASM, a Chinese professional sand maker manufacturer, further optimizes the structure and function of traditional verticalshaft impact crushers and launches a new generation of sandmaking and reshaping machine with high ...

cement mill t h prices Minerales de Malasia. Cement mill t h prices Mining Machinery Co., Ltd. Cement Roller Mill 15t H . Vertical Cement Grinding Mill From 10 20 T H Vertical cement grinding mill from 10 20 t h Cement Kilns Size Reduction and Grinding In the cement industry natural raw materials are processed to produce an end product which is a fine powder As shown in the flow diagram ...

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag It has the features of simple structure, low cost of manufacture and useVertical roller mill has many different forms, but it works basically the same

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small ...

Cement; Crushing Grinding; Vertical Roll Mill Drives. Delivering up to 3000 kNm torque, David Brown Santasalo vertical roll mill drives provide the optimum solution for grinding applications. Developed in cooperation with roller mill manufacturers, our vertical roll mill gearboxes combine strength and integrity, performing to the highest ...

Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding with its finer grinding requirements coming more ...

Vertical Roller Mill, Vertical Roller Mill Operation And . Vertical roller mill Introduction. The vertical roller mill which belongs to equipment for fine grinding, fine grinding of hard and medium hard or soft material in the building materials industry, especially used in the cement industry, ceramic industry, power sector, such as cement clinker, limestone, clay, China clay, .

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such ashigh grinding efficiency,low power consumption (2030% less power than ball mill),large drying capacity (simultaneously dry and grind materials with moisture up to 10%),large particle size of ...

Cement vertical roller mill adopts reliable structure and reasonable process flow, integrated with drying, milling, classifier, elevator. Especially, it can fully meets the requirement of clients in the high production of powder, and its main technical and economy indicator reachs the international level. crusher machine is mainly used in glass fiber industry, coal industry, chemical industry ...

Vertical roller cement mill thailand siam cement has ordered a lm 5633 cs vertical roller mill from loesche for its cement plant in kaeng khoi the mill will produce mediumfine cement qualities and is designed for grinding clinker gypsum and limestone.

WhatsApp)

WhatsApp)