Precision Balls Manufacturer Titanium, Gold, Steel | NEMB

New England Miniature Ball specializes in steel ball bearings, chrome balls, gold balls, titanium balls, stainless steel balls more. Call .

WhatsApp)

WhatsApp)

New England Miniature Ball specializes in steel ball bearings, chrome balls, gold balls, titanium balls, stainless steel balls more. Call .

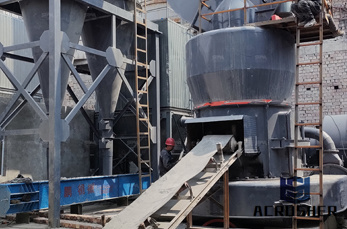

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

The Steel Ball Company''s grinding media is a valuable commodity widely used in power stations for coal grinding, limestone grinding for flue gas desulphurisation, cement production, aerated building block manufacturing and in the mining industry, especially in .

Steel Ball Manufacturing Process,Steel Ball Manufacturers in India, Steel Ball Manufacturing, Steel Ball Manufacturers, Steel Ball Manufacturers in Jaipur

MetalBall, high precision ball manufacturer. MetallBall is a French manufacturer of high precision steel balls and ceramic balls. We hold all the required production and inspection tools to satisfy the most critical requirements such as aerospace, space and medical.

The second production step is the rolling between plates with concentric grooves in order to eliminate the heading witness marks and to increase the precision of the ball. In this operation, the spheres are ground between two concentric pressure plates to correct the spherical shape and remove the seam formed in the cold forging.

Manufacturing Process. Standard Steel Ball Production. 1. Heading. Ball blanks are cold or hot headed from rolls of wire or bar stock depending on their size and the material. The heading machine cuts off a short cylinder of the material and a moving die with a concave spherical cup drives the cylinder into a matching cup in a fixed die. The ...

Titanium balls are widely used in aircraft, medical, industrial and jewelry industries. Abbott''s precision finish ensures surface uniformity and aesthetics for jewelry use. Since Abbott balls are free from pits, cuts or other surface imperfections, they are also perfect for use in body jewelry.

offers 27,300 steel ball making machine products. About 4% of these are other home product making machinery, 2% are other metal metallurgy machinery, and 1% are mine mill. A wide variety of steel ball making machine options are available to you, such as hot rolling mill, ball mill.

May 29, 2014· This video shows the steel balls manufacturing process by steel ball forming machine, also called steel ball skew rolling machine. Skew rolling forming process is a new technology to produce the ...

Grinding Ball, ALLSTAR INDUSTRY GROUP LIMITED, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tons.

We have developed a method by which entire production lots are checked for metallurgical integrity, keeping rejection to a minimum. However, products passing this process are guaranteed a maximum of 2% ball breakage in normal and correct mill operating conditions. MINMETALS HAND FORGED BALLS ''ZERO CR CAT 2'' GRINDING MEDIA 80125MM .

We are specialized in manufacturing grinding media ball mold equipment. View the video about the manufacturing process of grinding media balls and .

Mar 28, 2017· Ball bearings are manufactured in hundreds of sizes, from the ultrasmall 1. 50 mm diameter bearing for use with miniaturized medical devices and micromotors, to bearings over 15 feet in diameter for use in heavy equipment. How are ball bearings made, and how do they get the balls so round. The answer is a multistep manufacturing process involving .

Nov 14, 2019· Methods for manufacturing steel have evolved significantly since industrial production began in the late 19th century. Modern methods, however, are still based on the same premise as the original Bessemer Process, which uses oxygen to .

Manufacturing process of grinding media balls:For the production of grinding balls Energosteel uses hot rolled round bar from medium and high carbon and lowalloyed steel produced by the world''s leading metallurgical companies Prior to the production the preform is subjected to strict control against .

With sincerity and hard work of our professionals, we have carved a niche for ourselves in this domain by providing a premium quality gamut of Steel Grinding Media Balls. We provide our clients with a superior quality range of Hyper Steel Grinding Media Balls. Fabricated using high quality raw .

Nov 11, 2015· This edition of the series of programs explaining the technology used to produce items that are familiar in our daily life features ''Steel Balls''. A bicycle wheel spins smoothly because the ...

In essence, the process of making a toy balloon involves dipping a mold into liquid latex. The mold, or form, is shaped like a deflated balloon. The earliest balloon forms were disposable, made from cardboard attached to dowels. Modern forms are reusable and usually made from stainless steel, aluminum, or porcelain.

Manufacturing process of grinding media balls. Incoming inspection of preform For the production of grinding balls Energosteel uses hot rolled round bar from medium and high carbon and lowalloyed steel produced by the world''s leading metallurgical companies Prior to the production the preform is subjected to strict control against the chemical composition and .

Abbott manufactures over five billion balls each year in a range of sizes and materials. Most are of stainless or carbon steel, while the rest are from brass, aluminum, chrome steel, precious metals, offers glass and plastic.

Smart manufacturing in steel to achieve a podium finish By: Dr. Andrew Zoryk To make an analogy with one of my favorite sports—Formula 1 motor racing—oftentimes success and a topthree podium finish hinge on critical decisions that are made in real time.

The Manufacturing Process There are four major parts to a standard ball bearing: the outer race, the rolling balls, the inner race, and the cage. Races 1 Both races are made in almost the same way. Since they are both rings of steel, the process starts with steel tubing of an appropriate size.

Ball Chain Manufacturing is the worlds largest manufacturer of ball chain. All of our chain is made in the USA and sold at low wholesale, factory direct prices.

WhatsApp)

WhatsApp)