clay ore processing for cement YouTube

May 17, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)

May 17, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the main ingredient of cement—that is finely ground with gypsum and other chemical additives to produce cement.

The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay. Suitable reserves can be found in most countries. These raw materials are extracted from the quarry by blasting. They are then crushed and transported to the plant where they are stored and homogenized.

Feb 16, 2016· A stacker reclaimer for Limestone storage is shown in the video in a cement plant. Stackers and reclaimers are used in stockyards to stack minerals, ore, and other granular raw materials in ...

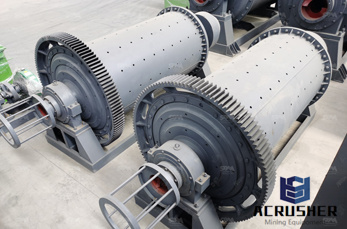

In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production.

Aug 15, 2017· Hi, Following three distinct operations are involved in the manufacturing of normal setting or Portland ordinary cement: 1. Mixing of raw materials 2. Burning 3. Grinding MIXING OF RAW MATERIALS The raw materials such as limestone or chalk and sha...

Bentonite is a type of clay that has an ability to swell and gel when dispersed in water which is used in construction mainly in excavation and foundation works. The word Bentonite is a toponym taken from a place called Fort Benton in USA, where it was discovered as a clay ore. Bentonite is of a ...

The cement industry has for some time been seeking alternative raw material for the Portland cement clinker production. The aim of this research was to investigate the possibility of utilizing iron ore tailings (IOT) to replace clay as aluminasilicate raw material for the production of Portland cement clinker. For this purpose, two kinds of clinkers were prepared: one was prepared by IOT; the ...

various clay ore processing for cement. what is clay in cement Concrete Brick, between 40 and 80 grams per minute per 30 sq. in. Or, in simple terms, Concrete Brick absorbs approximately 23 times more moisture in the same amount of time as does Clay Brick. If you examine the walls of clay brick and concrete brick ...

clay ore processing for cement, SAM screen can separate the stuff of different size range It is the most general means of size control in aggregates processing Chat Online >> Clay Ore Ore Crushing Solutions . Get Information; Cement, How It Is Produced Mine .

Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.

ZENTIH crushers, grinding mills, screening and sand washing machines are widely used in construction and mining industry for manufacturing building aggregates, sand gravel and ore processing. These machines are of highpower and lowconsumption. ZENTIH not only offer single machine, but also provide crushing and grinding solutions for every application.

Clay, Concrete, Glass and Stone Processing Machine Operators nec; Australian Jobs In Demand. ANZSCO ID 711199 Clay, Concrete, Glass and Stone Processing Machine Operators nec . This occupation group covers Clay, Concrete, Glass and Stone Processing Machine Operators not elsewhere classified.

clay content of concrete aggregates. 2. To determine the effects of clay content on the strength, shrinkage, and durability of concrete. 3. To relate these effects of clay on the properties of concrete to results of tests for determining clay con tent of the aggregates. This research included a .

Cement Cement Extraction and processing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary. Some deposits are mined by underground methods. Softer rocks such as chalk and clay can be dug directly by excavators.

Aug 30, 2012· Cement Manufacturing Process Phase 1: Raw Material Extraction. Cement uses raw materials that cover calcium, silicon, iron and aluminum. Such raw materials are limestone, clay and sand. Limestone is for calcium. It is combined with much smaller proportions of sand and clay. Sand clay fulfill the need of silicon, iron and aluminum.

clay ore processing for cement in south africa. clay ore processing for cement in south africa Cape Bentonite Mine I Bentonite I Zeolite. The Cape Bentonite deposit is a Sodiumbased Bentonite. Sodium Bentonite consists principally of one of the Smectite group of clay and company IMERYS South Africa, GET PRICE>>

Cement Crushing Grinding Plant. introduction; ... cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material during cement production.

Then it is transported by trucks and unloaded into the hopper of a clay crusher. They are three types of clay used in cement manufacturing, namely silty clay, Zafarana clay, and Kaolin. Other raw materials are used to control the kiln feed mix design, namely sand, and iron ore.

Cement Production HIGHLIGHTS PROCESSES AND TECHNOLOGY STATUS – The manufacture of cement is a twophase process. Clinker is first produced in a kiln system from calcareous (limestone, chalk or marl) and argillaceous (clay or shale) materials, with addition, in some cases, of small amounts of corrective materials (sand, waste bauxite, iron ore).

The process of calcination derives its name from the Latin calcinare (to burn lime) due to its most common application, the decomposition of calcium carbonate to calcium oxide and carbon dioxide, in order to create product of calcination is usually referred to in general as "calcine", regardless of the actual minerals undergoing thermal treatment.

To solve the problem of treating and leaching a clay ore in which the gold was finely disseminated, the author was able to suggest a unique method which he had seen described twentyfive years previously in a paper, "Occurrence and Treatment of Gold Ore at Bidi, Sarawak, Borneo," by T. C. Scrutton, which appeared in Trans. 15, I. M. M.,, in which clay ore was treated by leaching ...

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the main ingredient of cement—that is finely ground with gypsum and other chemical additives to produce cement.

Cement, mining, processing,Information. Cement, or Portland cement, is defined as "a hydraulic cement, obtained by burning a mixture of lime and clay to .

WhatsApp)

WhatsApp)