Sample Drying Calculations YouTube

Aug 21, 2017· A video presentation by Donald G. Mercer.,, P. Eng., FIAFoST, Department of Food Science, Ontario Agricultural College, University of Guelph.

WhatsApp)

WhatsApp)

Aug 21, 2017· A video presentation by Donald G. Mercer.,, P. Eng., FIAFoST, Department of Food Science, Ontario Agricultural College, University of Guelph.

Mar 09, 2006· Simple torque calculation for belt conveyor i need a simple (or estimate) formula to calculate torque (to turn)for belt conveyor application based on belt length, overall load, belt speed, pully drum diameter, and incline angle.

Charts Tables Find helpful reference materials quickly from Abrasive profile charts to Wet film thickness requirements ... Drum Measurement . Dew point calculation chart in Frenheit. Fractions. Decimal and metric equivalents of fractions. Heat Calculation Chart . Heat Calculation Chart .

The voltage I was referring to was the Power supply which originates from that off board power transformer. It is 16v 17v then regulated down to 5v for the micro etc. There is often a button magnet on the belt pulley, others have a opto sensor on the motor itself. The 22v is what you would read...

Calculate Tangential Force, Torque, and Machining Power for End Milling Applications. ... Home / Resources / Engineering Calculators / End Milling / Force, Torque, and Power. Force, Torque, and Power For End Milling Application. ... Reduced feed per tooth: in. (chip load at the cut) mm/min (chip load at the cut) F p Feed rate: IPM (with ...

8" interchangeable drum mill will be capable of running 5,000 OZ. coils of sterling silver . ... Touch screen will display torque on universals, load on mill heads, mill speed, mill load in amps, and roll temperatures. 50,000 LBS load cells will be installed in each mill head.

Calculate Tangential Force, Toque, and Machining Power for Face Milling Applications.

Outotec® is one of the largest mill suppliers in the world and has over 100 years of experience with grinding technologies. Our dedicated team of specialists provides engineering, project management, testing, and analysis services to ensure your grinding solution helps to liberate your profit. OUTOTEC GRINDING TECHNOLOGIES BENEFITS

This is a Government (USG) Information System (IS) that is provided for USGauthorized use only.

Provided Thickness is the thickness originally provided by the designer; a result of design calculations that include the Corrosion Allowance (CA) and the additional thickness available due to a higher nominal thickness that was selected from standard plate thicknesses available that will include mill tolerances.. CA Tmin is the minimum thickness that would initially be used to calculate ...

Follow our simple steps below to calculate capacity and find the freeze dryer that best fits your needs. ... Enter the number of trays you wish to load per run in the field "Number of Trays". 4) Click the "Calculate" button next to "Number of Trays". The fields for Total vials and shelf space will populate.

Before starting on a big project with a material that shrinks, make a test object to determine the projected amount of shrinkage, so that you do not end up with the material that does not fit correctly after washing. Calculate the shrinkage percentage after determining the original size and the end size.

An example of rolled material would be a rolled carpet or a rolled sheet of paper from the paper mill. The length units that can be used are yard, feet, inch, meter, centimeter, millimeter, mil, and micron. A mil is equal to one thouh of an inch. ... Calculator for Thickness of Roll of Material on Two Rims:

It is often necessary to determine how much of a given cable or wire will fit onto a spool or reel. This article provides a relatively simple method to calculate the approximate maximum length if you know the cable''s diameter and the reel''s dimensions.

Oct 10, 2017· xo tour llif3 played on a drum calculator and 2 cat pianos ... rockstar played on a cat piano,a drum calculator and its ... but i played it on a drum calculator and 2 cat pianos ...

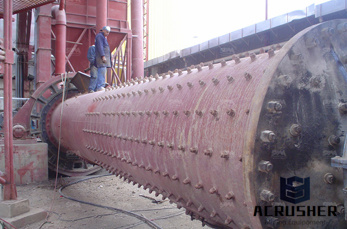

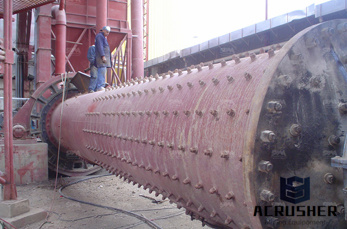

Rod mills are very similar to ball mills, except they use long rods for grinding media. The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill. To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at to

Nov 07, 2016· Fan motor CALCULATIONS, Pulley size, RPM, air flow rate cfm hvac rtu Duration: 9:58. The Engineering Mindset 118,191 views

Circulating load calculation made in a mill re vrm and ball mill circulating load mainly in usa the term circulating load is more often used than get price circulating 2011 04 09 crusher circulating load calculation and designing plants there is a need for calculating the circulating load of closed circuits how to calculate .

Jun 02, 2013· SPINNING CALCULATIONS Conversion of Weight units Ø 1kg = lbs Ø 1kg = 1000 grams Ø 1gm = grains Ø 1lbs =...

May 10, 2010· Thermal Relief Rate Calculation posted in Relief Devices Forum: Please any one help me to calculate the Thermal relief rate for the following case: This relief valve is for relieving cooling water from shell side. Hot fluid is one the tube side.. Case is thermal expansion of cooling water due to heating by hot fluid with system blocked in on Shell side. I got the formula from API520.. But ...

cific formula and constants to calculate overhung load. They also publish specific overhung load ratings for each speed reducer product that they produce. It is very important to use the correct overhung load calculation procedure in conjunction with the manufacturer''s accompanying overhung load rating.

sacme mtd ball mill . molino triturador sacmi mtd 340 Molino de bolas Flotación, ... » vacancy for pulp mill incharge in paper mill » hammer mill hammer mill model no: cf158 » drum mill mtd 120 loadin calculation » calculation of grinding media in ball mill » stone grinder pin mill colloid mill hammer mill » what coal . Get Price

Calculate Speed and Feed for Turning Applications. These calculations are based upon theoretical values and are only intended for planning purposes.

The average particle is subjected to an action similar to many sets of rolls in series, before it is discharged. Because of this, the rod mill can effectively reduce 1″ feed size to 10 mesh or finer in open circuit. The voids (or interstitial space) within a rod load are approximately half those in a ball mill grinding load.

WhatsApp)

WhatsApp)