The Working Principle of Hammer Mills (Stepbystep Guide)

impactor and hammer mill animations mmmetals. hammer crusher animation YouTube. Aug 26, 2013 . Hammer Mill Animation Hammer Crusher: Crusher is a machinery in ...

WhatsApp)

WhatsApp)

impactor and hammer mill animations mmmetals. hammer crusher animation YouTube. Aug 26, 2013 . Hammer Mill Animation Hammer Crusher: Crusher is a machinery in ...

30 Innes Road (cnr Graniet Rd), Jet Park Ext. 66 Boksburg, Gauteng South Africa

Hammer Mill operation and Maintenance. Up running hammer mills combine impact and shear to reduce material. Down running hammer mills primarily use shear by immediately taking feed to the screen or grate bars where hammers shear the material, until it passes through the openings.

DESIGN AND EVALUATE OF A SMALL HAMMER MILL. MOHAMED, T. H., H. A. RADWAN, A. O. ELASHHAB and M. Y. ADLY* ... in case a hammer comes in contact with a material hard to break at the first impact.

Sep 23, 2014· Hammer mills work in the principle that most materials will crush, shatter, or pulverize upon impact. 4. The Process: Material is fed into the mill grinding chamber through the feed chute, typically by gravity. It repeatedly is struck by ganged hammers which are attached to a shaft which rotates at high speed inside the mill chamber.

An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the difference between hammer mill and impact crusherShanghai . What''s the difference between jaw crusher and impact crusher? 2 years ago . horizontal shaft impactor and vertical shaft impactor.

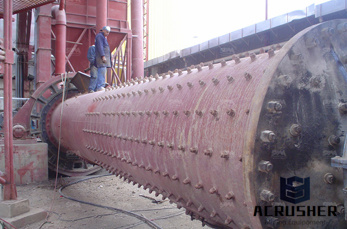

The study of project deals with the hammer mills employing a high speed rotating disc, to which an ''n'' number of hammer bars are fixed and swung outwards by centrifugal is fed in, either at the top or at the Centre, and it is thrown out centrifugally and crushed between the hammer bars or against breaker plates fixed around the periphery of the cylindrical casing.

Champion hammermills are capable of finegrinding either friable or fibrous materials and are designed to meet almost any particle size reduction need with high efficiency.

Denver, Co. GrandSlam™ sizereduction impact crusher replaces old primary clay crusher and two hammer mills for an increased grinding efficiency of 20% and replacement part savings of thousands of dollars. By Dennis Gilmour, President, Stedman Machine Company. Robinson Brick Co., Denver, Colorado. was formed in 1880 and is the oldest and largest brick manufacturer in Colorado.

The highshear/lowresistance cutting action of the hammer tips rotating at speeds up to 270 MPH, together with the rotational inertia of the heavyweight rotor assembly, reduces higher volumes of materials and yields greater output per horsepower/kilowatt than with many other types of mills.

Decades of experience and highly qualified product specialists make us a strong partner in the supply of hammer mills for size reduction. The ANDRITZ range of hammer mills covers the need for extremely fine or coarse grinding at high capacity.

Hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact. Material is fed into the mill''s chamber through the feed chute, typically by gravity, where it is struck by ganged hammers attached to a shaft that rotates at high speed inside the mill''s grinding chamber.

Hammermill. ® Paper for Life. ® Hammermill paper is scientifically designed and rigorously tested to perform at the highest level everytime. For over 100 years, we have been dedicated to helping people capture ideas, share thoughts, and show their work at its best at work, at home, and in school.

Hammer Mills Williams manufactures a large variety of hammer mills and hammer crushers wellsuited to handle limestone crushing applications. As the manufacturer holding the very first hammer mill patent to utilize midair impact crushing, Williams takes great pride in providing quality, rugged machines for many applications.

Scrap metal recycling uses screen openings up to 3″ x 3″ in the larger primary hammer mills, and punch plate holes as small as 1/4″ in our printed circuit board (PCB) recycling hammer mills. Mt. Baker Mining and Metals'' hammer mills are industrial grade, continuous duty machines.

The basic difference between a hammer drill and an impact driver is the direction from which they each exert additional force on their twisting action. A hammer drill exerts greater force directly into the bit as it hits the material being drilled, while an impact driver increases the force being delivered perpendicular to the bit.

Type GP Hammer Mills. The Williams GP, or General Purpose Hammer Mill, is a simple, rugged answer to many small and medium capacity grinding Type GP hammer mills can be equipped with a variety of hammers—both swinging and rigid—as well as screens, breaker plates and covers to do the required work economically.

RSG Inc, located in Sylacauga, Alabama specializes in fine powder technology. The company manufactures air classifiers, ball mills and stirred media mills for the production of fine, superfine and ultrafine powders for the mineral, mining, cement, lime, metal powder and chemical industries.

Jul 20, 2019· Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case. It produces size reduction by impact.

Jaw crusher, impact crusher and cone crusher are most selling stone crushers in modern crushing plant. PE jaw crusher is important primary crushing equipment in crushing plant, which is famous for high reduction ratio and great crushing capacity. ...

Hammer Mill Operating Principle. We have never subscribed to the idea that the hammermill is suited to the primary breaking of shovelloaded, quarryrun, or ROM minerun rock and ore. Even though the material be nonabrasive and quite friable there are other machines which are better fitted for such work.

Compared with the hammer crusher, the rotor of impact crusher is more suitable to crush the more hard material and saving energy. The size of the discharging particle''s adjusting range of the impact crusher is large, and it can be adjusted very simply.

Hammermill. ® Paper for Life. ® Hammermill paper is scientifically designed and rigorously tested to perform at the highest level everytime. For over 100 years, we have been dedicated to helping people capture ideas, share thoughts, and show their work at its best at work, at home, and in school.

28" International Standard/Impactor Hammermills. As an impactor, the 28" International Standard hammermill is specially designed to crack and separate seeds for the oilseed industry. With a tip speed of 22,020 ft./min. and a horsepower range of 75 to 335 HP, the 28" International Standard/Impactor consistently delivers for your oilseed needs.

WhatsApp)

WhatsApp)