Coal Fired Power plant Pulverizer CD is consuming more ...

RE: Coal Fired Power plant Pulverizer CD is consuming more power PersonalProfile (Mechanical) 19 Sep 15 01:53 There are a number of variables that we are not able to review remotely.

WhatsApp)

WhatsApp)

RE: Coal Fired Power plant Pulverizer CD is consuming more power PersonalProfile (Mechanical) 19 Sep 15 01:53 There are a number of variables that we are not able to review remotely.

coal to pulverizer for power plant. coal to pulverizer for power plant XSM excellent mining crushing machinery products or production line design, the company is ... Chat Free Construction of Coalfired Supercritical Pressure Power ...

pulverizer crusher machine for coal power plant. power plant coal mill pulverizer power plant coal mill pulverizer excellent mining crushing machinery products or production line design, the company is committed to building the Chinese brand mine crushing and processing machinery, mainly crusher, mill, sand making our products (power plant coal mill pulverizer) in more than one hundred of the ...

Figure 1: Coalfired Power Plant. Process. Coal is transported to the coal bin by use of a conveyer from the coal stock piles or railcar unloading stations. From the coal bin, the coal is fed into the coal pulverizer and dried using ~300° F air . When coal is pulverized, the process grinds the coal into a fine dust which expands the coal''s ...

Jan 13, 2020· coalfired power plants shut down at the secondfastest pace on record in 2019, despite President Donald Trump''s efforts to prop up the industry, according to data from the federal ...

A coalfired power station or coal power plant is a thermal power station which burns coal to generate power stations generate over a third of the world''s electricity but cause hundreds of thousands of early deaths each year, mainly from air pollution.. A coalfired power station is a type of fossil fuel power coal is usually pulverized and then burned in a ...

A coalfired thermal power station is a power plant in which the prime mover is steam driven. Water is heated, turns into steam, and spins a steam turbine, which drives an electrical generator, as schematically shown in Fig. it passes through the turbine (one to three stage), the steam is condensed in a condenser and recycled to where ...

coal fired power plant pulverizer parts. Opportunitities to Improve the Efficiency of CoalFired Power Plants. Apr 16, 2010 Since 1990, coalfired power plant efficiency has been flat while China has dramatically pulverizer clearance and settings Turbo Parts.

Nov 30, 2015· Coal pulverizers are the heart of a pulverized coalfueled boiler. ... Take These Five Steps Now to Ensure ELG Compliance at Your Power Plant . by ... One 450MW coalfired .

pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

coal fired power plant pulverizer Construction Waste Crusher Construction waste refers to the construction, construction units or individuals to construct, lay or demolish all kinds of buildings, structures and pipe networks, etc., and generate the spoil, spoil, waste, residual mud and other wastes generated during the repairing process.

number of pulverizers in coal fired power plant. Coal mill pulverizer in thermal power plants. Nov 17, 2012 coal mill/pulverizer in thermal power plants shivaji choudhury 2 1Introduction Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form Pulverized coal achieved its first commercial ...

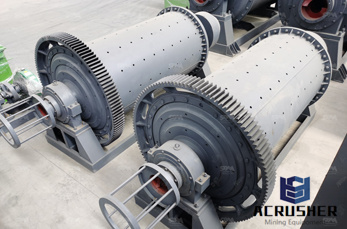

Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two.

Nov 17, 2012· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

Typical maintenance costs and intervals for each pulverizer gearbox were as follows: Oil changes required every 12 months at a cost of 5,000 in material and labor and 20,000 to 50,000 in lost electrical production, typical of most coalfired power generation units of this timeframe. This particular plant had 13 of these coal pulverizers ...

Combustion Engineering for Coal Fired Power Plants: Boiler Equipment, Boiler Piping and Instrument Diagrams, NFPA 85 Code (Boiler and Combustion Systems Hazards Code), Combustion Control, Oxygen Trim, Control of Air and Coal Flow into the Boiler, Matching Boiler Firing Rate Demand to Electrical load, NOx and SOx Control, Burner Management Systems, Boiler Permissive Starting Logic .

Apr 20, 2015· Depending on the size, a single plant can have more than 25 coal pulverizers. Coal pulverizing allows for less emissions and more efficient use of the fuel. The coal burns to create the steam that turns the generators and provides electric power. Large electric motors use a worm gear arrangement to drive the coal pulverizers and a blower that ...

scribd ppt on bowl mill used in power plant. alstom power plant coal grinder pulverizer 25700 alstom power coal pulverizer ppt on hp 1103 product template ppt on hp 1103 pulverisers in power plant ball mill slide ppt HP 1003 DYN pulverizing Alstom stone crusher plant crusher hp 1103 coal pulverizer Rocks Process KWS .

With more than a century of experience, Riley Power Inc. is a highly respected manufacturer of steam boiler parts and fuel burning equipment for all types of fossil and waste fuel fired boilers, including those that fire coal, oil, gas, as well as waste fuels including refuse, wood and cellulose byproducts.

Number Of Pulverizers In Coal Fired Power Plant. Every solutionmake is the effort of all our Workers, Engineers and Professionals. Our Hot Product

Pulverizer Wikipedia

A pulverized coalfired boiler is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox.. The basic idea of a firing system using pulverised fuel is to use the whole volume of the furnace for the combustion of solid fuels.

Coal mill pulverizer in thermal power plants. pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill.

tries besides coalfired electric power. Coal pulverizers are the notable materialhandling component largely unique to coal. Elements of the Figure Distribution of Total Equipment Costs in a Conventional Supercritical Pulverized Coal–Fired Power Plant 6% 10% 35% 18% 4% 12% 5% 3% 1% 6% 1% SOURCE: Gerdes et al., 2010. RAND ...

WhatsApp)

WhatsApp)